When managing wastewater and sewage systems, selecting the right pump is essential for smooth operation and minimising the risk of blockages. Among the most commonly used pumps are vortex pumps and macerator pumps. Both are designed to transport waste and liquids, but they differ in their functionality, applications, and performance. This guide will explain the differences between vortex and macerator pumps, helping you determine the best pump for your needs.

How Vortex Pumps Work

Vortex pumps, also known as recessed impeller pumps, utilise a unique design to create a vortex inside the pump chamber. The impeller sits back from the housing, reducing direct contact between the impeller and waste material. As the impeller spins, it creates a swirling vortex that pulls waste through the pump and discharges it efficiently.

This design is particularly effective in allowing larger solids and fibrous materials to pass through without clogging the pump, reducing wear and tear over time.

How Macerator Pumps Work

Macerator pumps feature a cutting mechanism that breaks down solid waste before it is pumped. The rotating blades chop solid materials into fine slurry, which can easily travel through narrow pipes. This grinding action ensures that even tough and fibrous materials are broken down into manageable sizes for smooth transport.

Best Applications for Vortex Pumps

Vortex pumps are ideal for systems where large solids or debris may be present, and clogging is a primary concern. Common applications include:

-

Municipal sewage systems

-

Industrial wastewater treatment

-

Agricultural waste management

-

Handling large or irregular solids

These pumps are especially effective in environments where waste contains challenging materials like rags, fibers, and debris that might block traditional impeller pumps.

Best Applications for Macerator Pumps

Macerator pumps are perfect for environments requiring waste to be moved through narrow pipes or over long distances. Common uses include:

-

Residential and commercial bathroom installations

-

Marine and RV waste systems

-

Long-distance waste transfer (both horizontal and vertical)

-

Systems requiring waste to be finely processed

These pumps excel in confined spaces and are often used in situations where reducing waste to a fine consistency is essential to prevent blockages.

Advantages and Limitations of Vortex Pumps

Advantages:

-

Low risk of clogging due to recessed impeller design

-

Handles large, irregular solids with ease

-

Reduced wear and maintenance requirements

-

Ideal for high-volume and heavy-duty applications

Limitations:

-

Less energy-efficient compared to macerator pumps

-

Larger and heavier design

-

Not suitable for fine particle breakdown

Advantages and Limitations of Macerator Pumps

Advantages:

-

Efficient at moving waste through small-diameter pipes

-

Suitable for long-distance waste transport

-

Compact design, perfect for tight spaces

-

Effective at breaking down solid waste

Limitations:

-

Susceptible to wear from abrasive materials

-

Requires more frequent maintenance due to cutting mechanism

-

Higher energy consumption due to grinding process

-

Less effective at handling large, non-biodegradable solids

How to Choose the Right Pump for Your Wastewater System

When deciding between a vortex pump and a macerator pump, consider the following key factors:

-

Type of Waste: If your system deals with large solids or fibrous materials, a vortex pump is your best option. If the waste needs to pass through narrow pipes or requires fine processing, a macerator pump is more suitable.

-

Distance and Pipe Size: For long-distance waste transfer through small pipes, macerator pumps are more efficient. Vortex pumps are better suited for shorter distances with larger pipe diameters.

-

Maintenance Needs: Vortex pumps generally require less maintenance due to fewer moving parts. Macerator pumps may need more regular servicing, particularly the cutting blades.

-

Energy Efficiency: Vortex pumps are typically more energy-efficient for bulk handling, while macerator pumps consume more power due to the grinding mechanism.

-

Space Constraints: If you're working with limited space, the compact design of a macerator pump may be a better fit for tight installations.

Selecting the Best Pump for Your Wastewater Needs

By understanding the differences between vortex and macerator pumps, their respective benefits, and limitations, you can make an informed decision that ensures optimal performance and reliability for your wastewater and sewage management system.

Whether you need to handle large solids with a vortex pump or finely process waste with a macerator pump, choosing the right pump will improve your system’s efficiency and minimise the risk of clogs and costly repairs.

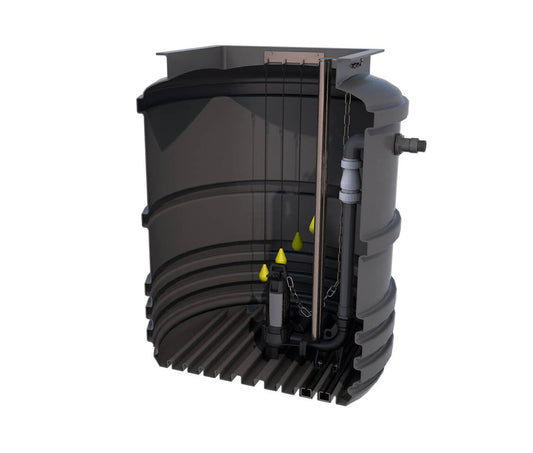

For high-quality Sewage pump stations, check out Cotterill Civils’ sewage pump station collection. For more information visit our website or contact our expert team today on 0121 351 3230

Alternatively, fill out our enquiry form: