Geosynthetics are man-made materials made from plastics used in various applications - usually for erosion control, soil stability or drainage.

In this article, we will compare Geogrids vs Geotextiles and tell you everything you need to know:

What is a geogrid?

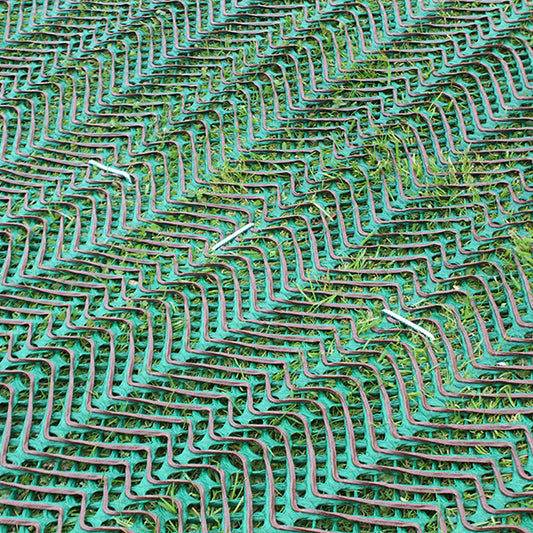

These are open mesh-like materials of integrally connected polymers. Geogrids are made from polyester, polyethylene, or polypropylene. They are used for soil or hardscape reinforcement and stabilisation; for instance, reinforcing a retaining wall backfill.

In most cases, geogrids are used in high-demand agricultural or heavy load situations due to their strength being greater than most geotextiles. Thanks to its low strain, geogrids are strong in tension, stretching only about 2 to 5% under load. Geogrids are produced in uniaxial (one-way) and biaxial (two-way) forms, with each being used for different applications.

Uniaxial Geogrid

Uniaxial geogrids, also sometimes referred to as “one-way” or “one-directional” geogrids, are geogrids that are only strong in one direction, even though they may look very similar to a biaxial geogrid. Uniaxial geogrids are typically used in scenarios where soils only require reinforcement in one direction – almost always in retaining walls or slope reinforcement scenarios.

Biaxial geogrids are sometimes referred to as “two-way” or “bi-directional” geogrids and are equally strong in two directions. This type of grid can be used in retaining wall construction, and can be rolled out along the retaining wall blocks, provided the roll width is wide enough to cover the geogrid design width. It’s typical use, however, is in roadway construction (including gravel driveways) and foundation improvement applications.

What are geotextiles?

Geotextiles are defined as any permeable textile used for dirt, soil, earth, or rock in any geotechnical engineering-related project or structure or system. They are the most widely-used geosynthetic for agriculture. There are both woven and non-woven geotextiles.

Woven geotextiles are composed of woven slit film polypropylene materials. This type of geotextile is made from two sets of parallel threads or yarns. They combine high strength and low permeability, making them very effective at bridging over wet or inferior soil layers.

Non-woven geotextiles:

Non-woven geotextile membranes are made from needle punched polypropylene, allowing simultaneous separation and filtration. Non-woven geotextiles combine the strength of woven fabrics with high permeability, making them a better choice when applications require both separation and filtration.

Geogrids vs Geotextiles

Unsure which product is the right choice for you? Here’s the difference between geogrids and geotextiles to help you decide:

- Geotextiles are manufactured for separation, filtration, and drainage purposes, whereas geogrids are manufactured specifically as a reinforcement material.

- It may seem that geogrids’ interlocking of the soil with the grid membrane makes it a superior form of reinforcement; however, the geotextile provides the separation function that ensures it maintains its thickness, service life, and long-term strength.

- Geogrids are passive resistance dependent reinforcement, whereas geotextiles are frictional resistance dependent reinforcement.

- Geotextile installation involves:

- Grading

- Evacuating

- Allowing vegetation, and

- Placing the separation geotextile directly on the prepared subgrade

- Geogrid installation involves:

- Planning the geogrid retaining wall

- Evacuating

- Sub-base and base stabilization

- Gravel levelling

- Laying retaining wall blocks

The main differences summarised are:

Geotextiles: Used primarily for soil separation to promote drainage. Generally allows very little to no soils to travel through, but does allow water to move freely.

Geogrids: Used primarily for soil reinforcement. Does not impede water or soils from travelling.

How can we help you?

Here at Cotterills we supply geogrids and both woven geotextiles and non-woven geotextiles - our experts can advise you on the best solutions for your applications. Give us a call on 0121 351 3230 or visit our website today!

Alternatively, fill out our enquiry form: