If you’re considering purchasing unperforated twinwall drainage pipes but you’re unsure how it differs from other pipes, here’s a helpful guide:

Contents

- What is unperforated twinwall pipe?

- What are the applications of unperforated twinwall plain end pipe?

- What is the difference between unperforated twinwall plain end pipe and other types of drainage pipe?

- Are unperforated plain end pipes easy to install?

- Can you get unperforated plain end pipes in different sizes?

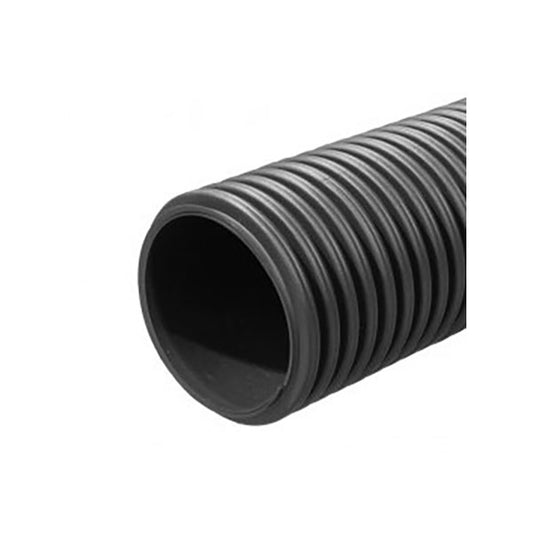

What is unperforated twinwall pipe?

Unperforated twinwall plain end pipe is a type of drainage pipe that is made of two layers of high-density polyethylene (HDPE). The outside of the pipe is corrugated which gives additional strength to the pipe. This additional strength and durability makes it suitable for use in a variety of applications, including drainage, culverts, and other underground installations. It is often used to redirect water to another location including to a stream, river, tank or soakaway.

The plain end of the pipe refers to the fact that it does not have any integrated coupling or connector on either end, allowing it to be cut size and joined using separate fittings or connectors. This makes it easy to customize the length of the pipe to fit specific installation requirements, making it versatile for a wide range of applications.

What are the applications of unperforated twinwall plain end pipe?

Unperforated twinwall plain end pipe is often used in situations where water needs to be moved away from a specific area or structure. This includes agricultural drainage systems, road drainage systems, and landscaping projects. The nature of the product’s durability and ability to withstand heavy loads and pressure make it ideal for use in these applications.

- Drainage: Twinwall plain end pipes are commonly used for drainage purposes, as they have a high flow rate and can withstand the weight of soil and other materials. They are often used in agricultural, construction, and civil engineering applications.

- Culverts: They are also used for culverts, which are structures that allow water to flow under roads, railways, and other infrastructure. The pipes can be installed quickly and easily, making them a popular choice for culvert construction.

- Sewerage: Twinwall plain end pipes can be used for sewerage systems, as they are resistant to chemicals and other substances that are commonly found in sewage. They are also resistant to corrosion, which makes them durable and provides a long lifespan for the product which also makes it low maintenance.

- Landscaping: Twinwall plain end pipes can be used for landscaping applications, such as for the construction of garden ponds, water features, and drainage systems for sports fields and parks.

What is the difference between unperforated twinwall plain end pipe and other types of drainage pipe?

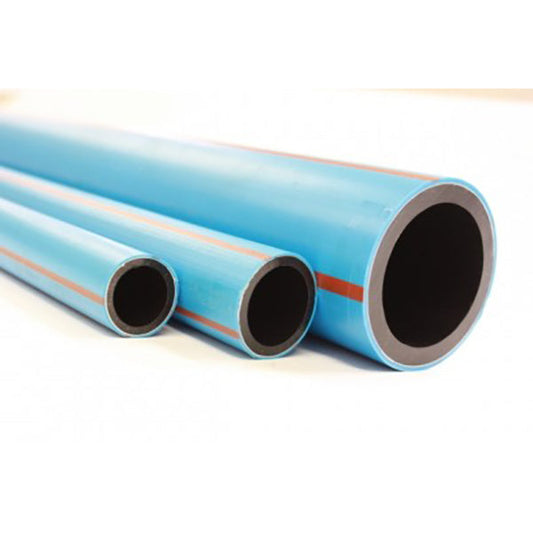

One key difference between unperforated twinwall plain end pipe and other types of drainage pipe is its unique design. The double layered HDPE nature of the pipe provides additional strength, allowing it to withstand heavy loads and pressure. Other types of pipe such as barrier pipe are made from MDPE instead of HDPE which makes them flexible as opposed to rigid, which makes them appropriate for different types of applications.

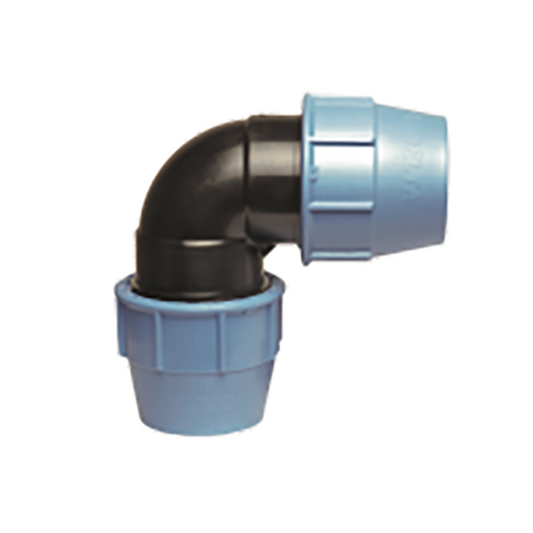

Another key difference is the plain end of the pipe. Unlike some other types of drainage pipe, unperforated twinwall plain end pipe does not have any integrated coupling or connector on either end, allowing it to be cut to length and joined using separate fittings or connectors. This makes it easy to customize the length of the pipe to fit the majority of project requirements.

Additionally, unperforated twinwall plain end pipe is designed for non-perforated applications. This means that the pipe is not perforated with holes or slots, as some other types of drainage pipe may be. Instead, it is designed to transport water away from a specific area or structure without allowing any to infiltrate the surrounding soil or drain into nearby waterways. This makes it ideal for use in areas where water needs to be moved away from a specific location and into another without leakage.

Are unperforated plain end pipes easy to install?

Unperforated plain end pipes can be installed quickly and with ease.

Made from HDPE (high-density polyethylene), unperforated pipes provide high strength and durability for various applications. They’re also lightweight, which makes them easier to transport, handle, and install.

A plain end pipe is a pipe that has been cut at 90° perpendicular to the pipe length run.

Unlike grooved, threaded, and bevelled end pipes, unperforated plain end pipes don’t have any integrated couplings or connectors. Therefore, they can be easily cut to size and connected with separate fittings or connectors – saving you both time and effort.

Can you get unperforated plain end pipes in different sizes?

Here at Cotterill Civils, our unperforated plain end pipes are available in 1m, 1.5m, and 6m lengths, and range from 150-1050mm in diameter.

We stock unperforated Twinwall plain end pipes in a range of sizes to accommodate the needs of all our customers and their drainage applications, so we are confident that you’ll find exactly what you’re looking for.

However, if you’re unsure which size best suits your project and application, or you can’t find the size you need, talk to our team of technical experts today.

Here at Cotterill Civils we have a wide range of unperforated and perforated twinwall plain end pipe, alongside barrier pipe, MDPE water pipe, twinwall ducting and much more. We have a range of pipe and fittings ready for immediate dispatch.

Our team of industry experts have over thirty years of experience, and are more than happy to give advice and guidance regarding the best products for individual applications.

Speak to one of our friendly members of staff today on 0121 351 3230.

Alternatively, fill out our enquiry form: